ELECTRIC VEHICLES: COMPONENTS AND WORKING PRINCIPLE

All-electric vehicles (EVs) have an electric motor instead of an internal combustion engine. The vehicle uses a large traction battery pack to power the electric motor and must be plugged into a charging station or wall outlet to charge. Because it runs on electricity, the vehicle emits no exhaust from a tailpipe and does not contain the typical liquid fuel components, such as a fuel pump, fuel line, or fuel tank.

All-electric vehicles (EVs) use a battery pack to store the electrical energy that powers the motor. EVs are sometimes referred to as battery electric vehicles (BEVs). EV batteries are charged by plugging the vehicle into an electric power source. Although electricity production may contribute to air pollution, the U.S. Environmental Protection Agency categorizes all-electric vehicles as zero-emission vehicles because they produce no direct exhaust or emissions.

Both heavy-duty and light-duty EVs are commercially available. EVs are typically more expensive than similar conventional and hybrid vehicles, although some cost can be recovered through fuel savings, a federal tax credit, or state incentives.

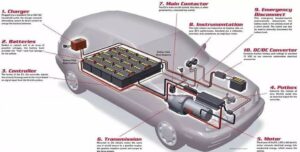

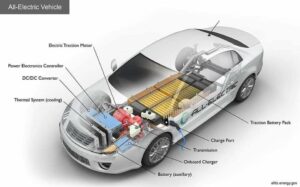

Components of an All-Electric Car

1. Battery (all-electric auxiliary):

In an electric drive vehicle, the auxiliary battery provides electricity to power vehicle accessories.

2. Charge port:

The charge port allows the vehicle to connect to an external power supply in order to charge the traction battery pack.

3. DC/DC converter:

This device converts higher-voltage DC power from the traction battery pack to the lower-voltage DC power needed to run vehicle accessories and recharge the auxiliary battery.

4. Electric traction motor:

Using power from the traction battery pack, this motor drives the vehicle’s wheels. Some vehicles use motor generators that perform both the drive and regeneration functions.

5. Onboard charger:

Takes the incoming AC electricity supplied via the charge port and converts it to DC power for charging the traction battery. It monitors battery characteristics such as voltage, current, temperature, and state of charge while charging the pack.

6. Power electronics controller:

This unit manages the flow of electrical energy delivered by the traction battery, controlling the speed of the electric traction motor and the torque it produces.

7. Thermal system (cooling):

This system maintains a proper operating temperature range of the engine, electric motor, power electronics, and other components.

8. Traction battery pack:

Stores electricity for use by the electric traction motor.

9. Transmission (electric):

The transmission transfers mechanical power from the electric traction motor to drive the wheels.

Driving Range

Today’s EVs generally have a shorter range (per charge) than comparable conventional vehicles have (per tank of gas). The efficiency and driving range of EVs vary substantially based on driving conditions. Extreme outside temperatures tend to reduce range because more energy must be used to heat or cool the cabin. High driving speeds reduce range because of the energy required to overcome increased drag. Compared with gradual acceleration, rapid acceleration reduces range. Hauling heavy loads or driving up significant inclines also reduces range.